Atoms vs Bits: The Growing Gap in Tech

In this article, “hardware” refers to manmade items composed of atoms in the general sense, not just computer equipment. Views expressed are not those of CadifyAI nor necessarily those of the author, rather they may be intended to provoke thought in the reader.

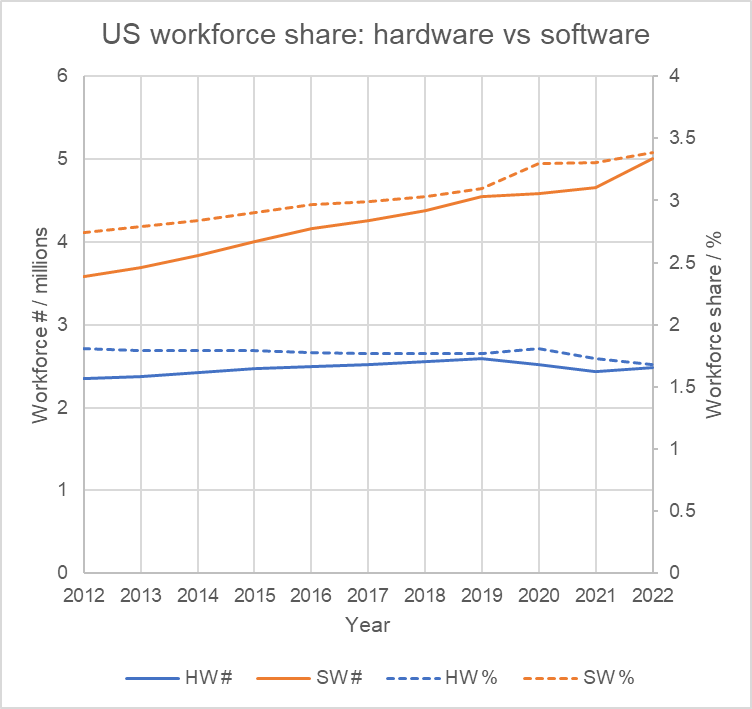

In 2022, there were 5.0M “bit flippers” employed in software jobs in the USA, up from 3.6M in 2012 – a 23% increase in share of the workforce. By comparison, there were only 2.5M people in hardware, 7% less in workforce share than a decade earlier. The gulf is widening between those working in the physical world of atoms vs those in the “virtual” world of bits. Should we be concerned? Will the trend stabilise anytime soon?

Of course, the trend is wholly unsurprising. From both a prospective employee or company founder’s point of view, software has a drastically lower barrier to entry. “Anyone with a positive attitude and a cheap laptop can contribute,” observes a16z’s techno-optimist manifesto. In contrast, to be taken seriously as a hardware engineer you usually need an engineering degree (4 years). Speaking of which, 6 years after graduation, only 38% of my (Jesus College, Cambridge) university engineering cohort actually work in hardware. 46% have defected to software. With student loans to repay, who can blame them? Graduate hardware jobs rarely fetch $50k per annum in the UK, whereas $125k+ isn’t unheard of for software grad salaries. Meanwhile, $500k+ is on offer for the crème de la crème of ML/AI programmers at OpenAI in Silicon Valley. Given the infancy of the field, many candidates considered world experts have less than 5 years’ experience wielding the tools of their trade. Not so for hardware engineering, where the rate of salary increase and career progression is much slower. 10 years’ experience might still class you as a padawan, whilst a senior engineer’s salary might top out at $75k. Impatiently ambitious people inevitably gravitate away.

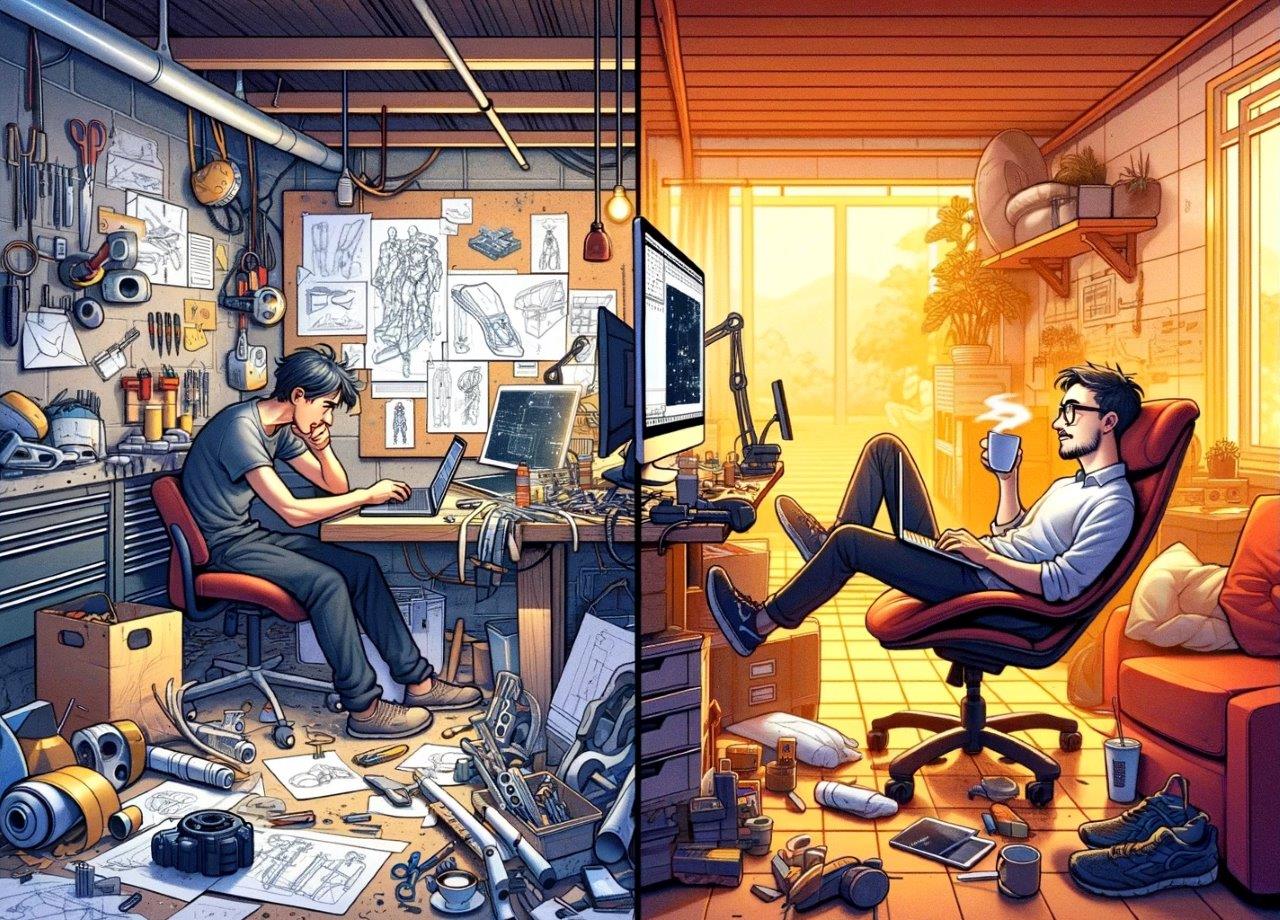

For a hardware founder, starting capital requirements run from a few thousand dollars for basic tools if you can get away with prototyping in your garage to several million for specialist machinery in a dedicated workshop or cleanroom. Obtaining funding is increasingly challenging, given that your business plan is vying for attention in a sea of software proposals promising infinite scalability, shorter payback periods and seemingly uncapped valuation growth. Software founders might feasibly have knocked up an MVP or at least a proof of concept tech demo by the time they start pitching for pre-seed. Hardware founders often have to fundraise purely on the strength of the vision and team.

Let’s say, against the odds, you’ve persuaded an investor to part with their dough. A newly minted software founder need only hire some programmers to crack on printing money. Neither a common workplace nor even timezone is a must. There is great latitude in working practice, accommodating a diverse range of talent from gig workers to digital nomads to fractional C-suite executives to nocturnal devs. If an office is desired, renting some desks in a trendy quarter of a happening city should provide a large enough catchment of brains. The demands of hardware prototyping, on the other hand, ordinarily require that the starting lineup be collocated and synchronous. Finding a suitable workshop with room or options to grow tends to push hardware companies out to industrial estates on the fringes of metropoli. Here in the outer reaches, talent is scarcer, relocation for work may be required – yet another obstacle to recruitment.

HR is just one of many recurring issues. Supply chains are reliably unreliable; now that they are all interconnected and globalised, knock-on effects abound, such as the delays to everything from space robots to washing machines due to the world semiconductor shortage. Supposing all ducks are in a row and sufficient contingency is in place to account for these operational trials and tribulations, the next and arguably most formidable challenge is designing and building a working product. Unlike the charmed software founder, who simply opens their favourite (likely free) IDE and starts typing, the long-suffering hardware founder probably has to fork out a small fortune for a CAD (Computer Aided Design) package just to advance their proposal beyond rough hand sketches. A first pass at the overarching structure, maybe sufficient to convey the design concept to investors, might take a few days. A few more to add rendering to whet customers’ appetites. Adding internal structure, details, fixings, fasteners etc: days to months, depending on project complexity.

But design is never linear – as it evolves, there is a constant stream of revisions, dimension changes, component substitutions, which get harder to implement as the complexity grows, layer upon layer of intertwined parameters impeding each subsequent modification. This is why days slip into weeks, months turn into man years. Design is by nature exploratory. There are many false leads and dead ends. Increasingly high fidelity simulations can now catch many of these before prototypes are manufactured and tested. Some invariably slip through the net, resulting in a graveyard of broken prototypes and if you’re lucky, valuable test data. Either way, the material and fabrication bills continue to rack up. How easy and fast it is to test software by comparison – results at the click of a button and effectively free but for the overheads.

Runway limitations might permit a hardware product only one or two redesigns before it has to be refined for production. The substantial cost in time and money of each iteration rarely allow a thorough sweep of the entire design space, so new inventions should be forgiven if they land far from the global or even local optimum. Evolution occurs incrementally when competitor companies emerge or on the timescale of product lines, if the original business survives long enough. Software, on the other hand…you get the picture. Don’t even get me started on manufacturing!

Why would anyone, given the choice, willingly go into hardware? Speaking for myself, I wanted to build tangible things (that I could strap myself into and take flight with, but that’s another story), though they’ve never yet been wildly profitable. I hope others too are willing to overlook the litany of seemingly unfavourable omens and to embark on quests down the road less traveled by. Despite the inexorable encroachment of the metaverse and the fact that humans now average 44% of their waking hours peering at screens, the world needs physical stuff.

Electrons will always be easier, cheaper and faster to manipulate than atoms. Bad news will always arrive before the swiftest spaceship. However, unless we make a concerted effort to reach beyond the low hanging fruit “and do the other things, not because they are easy, but because they are hard,” we will find ourselves in a hardware desert, where our ever more sophisticated software is held back by our comparatively antediluvian command of the material realm.